I. Case Overview

In China's energy consumption, industrial enterprises are the main group of energy consumption, and energy consumption accounts for about 70% of the total energy consumption in the country. The technological processes, installation conditions, product types, and energy management levels of different types of industrial enterprises affect energy consumption. Consumption will have different effects. Therefore, industrial enterprises can implement effective energy management and energy saving measures, which can not only help enterprises to save energy and reduce consumption, reduce production costs, improve corporate energy management, but also greatly relieve the huge pressure on energy supply for the entire society, and effectively improve the living environment. .

At present, a manufacturing company in Henan consumes a large amount of energy every year in production, but does not have a complete management system. It wants to establish an energy consumption management system to realize the entire process of informationization from energy data collection-process monitoring-energy consumption management, etc. Scientific management achieves the goals of energy conservation and consumption reduction and improvement of the overall energy management level.

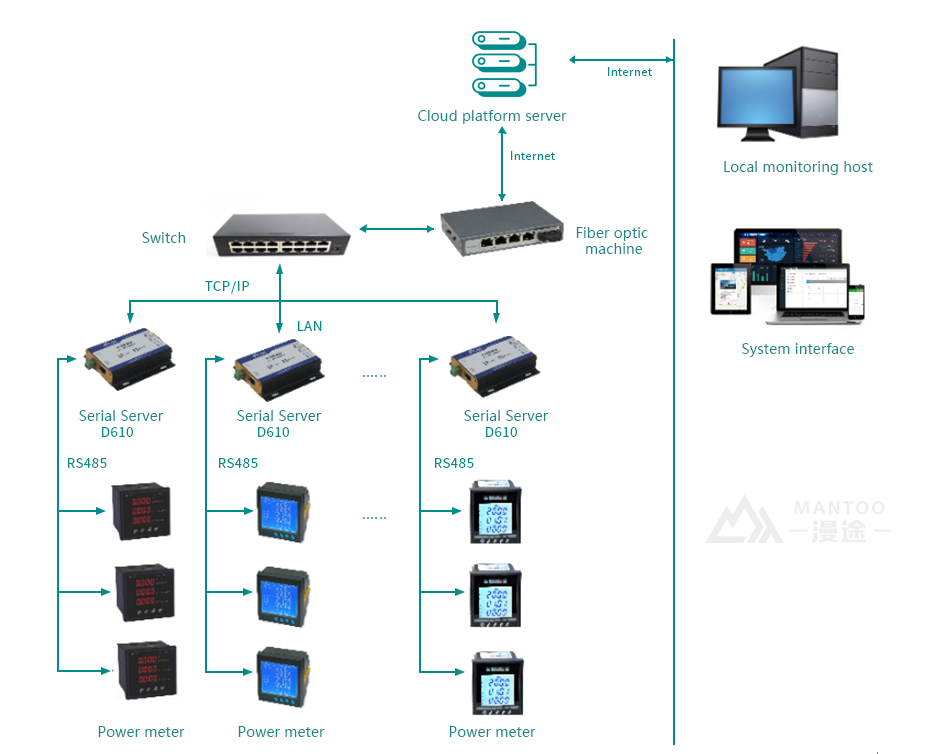

MANTOO, as an industrial IoT service provider with R & D and intelligent manufacturing capabilities in the Yangtze River Delta region, uses wireless transparent transmission technology and MT-D610 remote intelligent acquisition terminal (network port) to research and develop according to the company's needs. An energy management cloud platform system integrating data collection, key node monitoring, and data analysis and statistics is presented. This system helps the enterprise solve the problems of serious energy consumption, high production cost and low management level, and enables the factory to find high energy consumption nodes or unreasonable energy consumption habits through refined management, and further energy saving transformation or equipment for users The upgrade provides accurate data support and greatly improves the company's management level.

II. System architecture diagram

Ⅲ. System functions

※Online energy consumption collection: regional electricity consumption summary, department electricity ranking, itemized electricity statistics analysis, data inspection, real-time energy consumption data collection, current, voltage, and power online monitoring.

※Energy-saving visual kanban: The energy map of the factory, based on real-time data collection, forms a time chart of electricity consumption, a 3D pie chart of energy consumption, and 2D / 3D can be arbitrarily switched. Visual display of electricity demand.

※Fault monitoring: According to intelligent analysis of energy consumption data, determine whether the equipment works normally in real time.

※Trend forecasting: Analysis of the electricity consumption in the next stage through analysis of historical data and environmental factors will help companies to declare electricity, control costs, and use peak-to-peak electricity.

※Real-time alarm: The equipment failure can be reflected by monitoring the electrical parameters of the device. When the collected data exceeds the limit, the system automatically alarms. At the same time, it can also use the SMS method to support all-round and all-weather alarms. It also supports alarm logic customization and hierarchical alarm logic.

※ Process control: It collects electrical energy data of various states of equipment operation, real-time display on the platform side, and has the function of real-time control of each process on the platform side.

Ⅳ. Software system interface

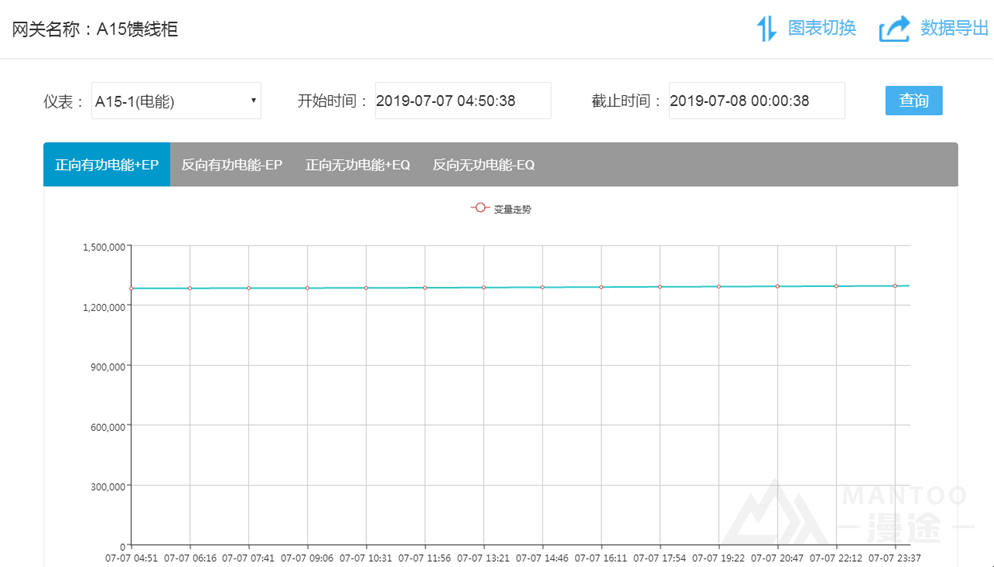

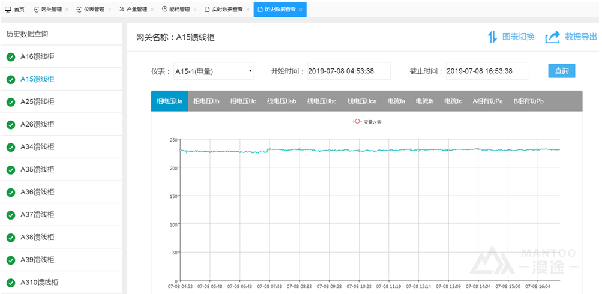

Data Display Interface

System Background

Real-time Data Display Interface

Historical Data Interface Diagram

Ⅴ. Hardware Product Introduction

Product introduction:

MT-D610 is a dual serial server. It is a device that realizes two-way transparent forwarding of data between serial and Ethernet ports. It adopts an industrial-grade design and supports RS-232 and RS-485 functions, but cannot work at the same time. Users can set Required serial port function. Serial port data is transparently transmitted on the serial port side, while TCP / IP data packets are on the Ethernet port side. The internal hardware TCP / IP protocol stack is integrated. Working details can be specified through simple settings. In the system, the data of each meter of the power distribution cabinet is mainly collected by RS485 communication, and the wired Ethernet technology is used for data transmission.

Ⅵ. Field application photos

Monitoring Center

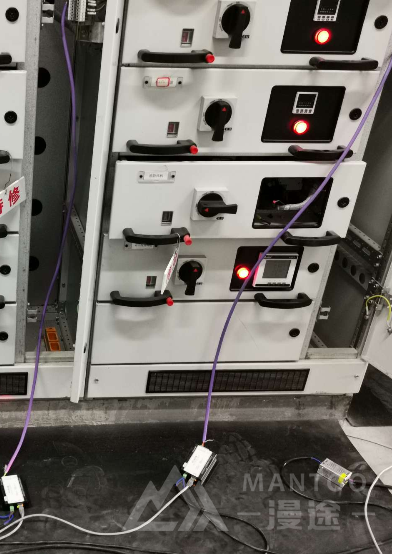

Field equipment installation

Energy data collection

Ⅶ. Customer Evaluation

The MANTOO Energy Consumption Monitoring System is specially developed for our company and mainly monitors the power usage. Our company is a high-energy-consuming enterprise, but the power usage of each device has always been a management difficulty. Manual meter reading is time-consuming and labor-intensive. Reporting also consumes a lot of energy. The energy management analysis system currently in use can conveniently collect the energy consumption of a single device. Combined with the equipment distribution, the single machine, production line, workshop, shift, weekly summary, free statistics and many other functions greatly facilitate our energy monitoring. Combined with the abnormal alarm, it is initially estimated that the energy management system can bring direct benefits of more than 8 million per year.