I. Project Background

As global climate change intensifies, "carbon peak and carbon neutrality" have become core strategies for countries to address the climate crisis. As the world’s largest energy consumer and carbon emitter, China set forth its dual-carbon goals in 2020—achieving carbon peak by 2030 and carbon neutrality by 2060—elevating green and low-carbon development to a national strategy. Against this backdrop, the shift from an extensive to a refined energy management model has become imperative. Energy monitoring systems, serving as core tools for "digitalized energy management," have been included as a key promoted area in national policies.

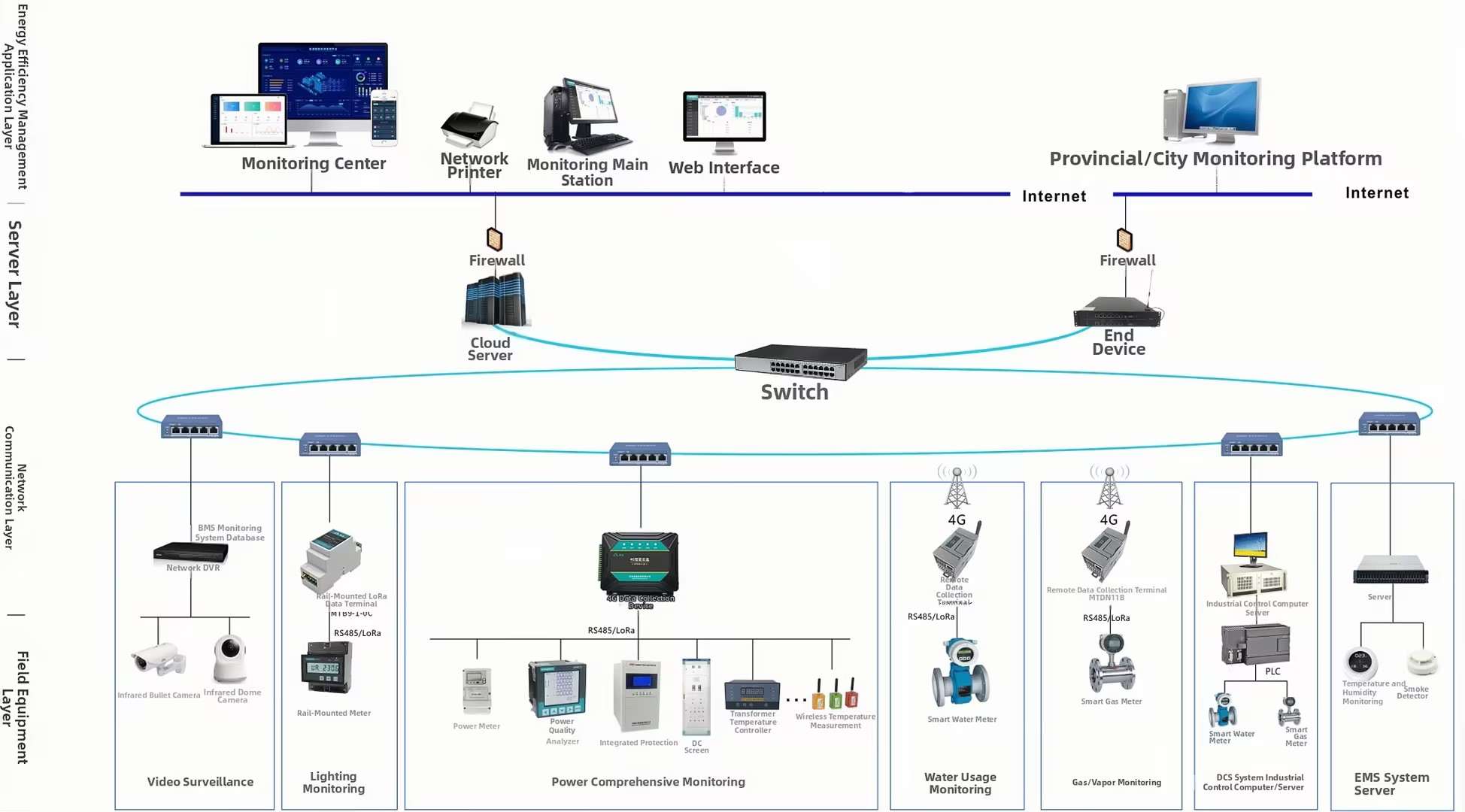

II. SYSTEM ARCHITECTURE

Networking Method | 4G or Ethernet |

|

Wireless Parameters | Industrial-grade wireless module | |

Standard | 4G Unicom version | |

Standards and Frequency Bands | LTE FDD: B1/B3/B5/B8;LTE TDD: B38/B39/B40/B41;TD-SCDMA: B34/B39 WCDMA: B1/B8;CDMA: BC0;GSM: 900/1800MHz

| |

Theoretical Bandwidth | LTE FDD: Downlink 150Mbps, Uplink 50Mbps;LTE TDD: Downlink 130Mbps, Uplink 35Mbps;TD-SCDMA: Downlink 4.2Mbps, Uplink 2.2Mbps;CDMA: Downlink 3.1Mbps, Uplink 1.8Mbps. | |

Transmit Power | <23dbm | |

Receiver Sensitivity | >-94dbm | |

Transmission Protocol | TCP、MQTT | |

Software | Configuration Method | Host Computer Configuration Software |

Interface Type | LAN Interface | One 10/100M Ethernet port (RJ45 jack) with built-in 1.5kV electromagnetic isolation protection. |

Serial Port | 1× RS485 interface, with built-in 15KV ESD protection; Standard: 3-wire (A, B, GND) Baud rate: 1200~38400bps. | |

I/O Port | 2× DI (wet contact 5~24V); 2× DO (AC250V/5A, DC30V/5A); 2× AI (accuracy: better than 0.1%) | |

Indicator Lights | Power and communication indicators | |

Antenna Interface | Standard SMA female antenna interface, characteristic impedance 50 ohms. | |

SIM Card Interface | Standard drawer-type user card interface, supports 1.8V/3V SIM cards, with built-in 15KV ESD protection. | |

Power Interface | DC power socket or terminal block, with built-in reverse connection protection. | |

Power Supply | Standard Power Supply | DC 12V/2A |

Power Supply Range | DC 9V~24V | |

Power Consumption | Standby State | 88mA@12V |

Communication State | 170mA@12V | |

Physical Characteristics

| Enclosure | Metal enclosure, safely isolated from the system, suitable for industrial control applications. |

Dimensions | 13.5*12.1*3.5cm | |

Storage Humidity | 5%~95% RH (non-condensing) |

4G | 4G Unicom Version |

|

Frequency Bands | LTE FDD: B1/B3/B5/B8; LTE FDD: B1/B3/B5/B8; LTE TDD: B38/B39/B40/B41; LTE TDD: B38/B39/B40/B41; | |

Theoretical Bandwidth | LTE FDD: Downlink 10Mbps, Uplink 5Mbps; LTE TDD: Downlink 7.5Mbps, Uplink 1Mbps LTE FDD: | |

Transmit Power | 23dBm±2dB 23dBm±2dB | |

Receiver Sensitivity | >-94dBm | |

Transmission Protocol | TCP, MQTT | |

LAN | 1× 10/100M Ethernet port (RJ45 connector), with built-in 1.5KV electromagnetic isolation protection. | |

Power Consumption | Standby State | 50mA@12V |

Communication State | 120mA@12V | |

Power Supply | Standard Power Supply | DC 12V/2A |

Power Supply Range | DC 9~24V | |

Indicator Lights | Equipped with power and communication indicator lights. | |

Interface Type | Acquisition Interface | 1× RS485 interface, with built-in 15KV ESD protection. |

Antenna Interface | Standard SMA female antenna interface, characteristic impedance 50 ohms. | |

SIM Card Interface | Standard drawer-type user card interface, supports 1.8V/3V SIM cards, with built-in 15KV ESD protection. | |

Power Interface | Terminal block, with built-in reverse connection protection. | |

Operating Environment | Operating Temperature | -35~80℃ |

Storage Humidity | 5%~95% RH (non-condensing) | |

Dimensions | Enclosure Dimensions | 80*46*63 mm |

Installation | Installation Method | Wall-mounted/35mm DIN rail |

Mounting Hole Dimensions | M4 |

IV. System Functions

Basic Functions: Login/Logout

Login: Access the system using a fixed username and password.

Logout: Users can exit the system to ensure account security.

Device Management: Gateway and Data Acquisition Device Configuration

(1) Add Gateway:

Enter basic gateway information (gateway name, gateway number), set the data collection frequency (only effective in passive collection mode), and save to complete gateway addition (deletion supported).

(2) Add Data Acquisition Device:

① Associate Gateway: Select an already added gateway.

② Enter Device Information: Device name, device number.

③ Configure Collection Parameters: If the gateway is in passive mode, enter the polling command (the query command sent by the host to the slave device).

④ Parsing Rules: Must fill in a JSON script (used to parse the data packets uploaded by the device; otherwise, valid data cannot be obtained).

(3) Edit Device:

Click the device number to enter the editing interface, where the following information can be adjusted:

Associated gateway;

Device name, device type;

Address code, polling command (effective in passive mode);

Data parsing rules (JSON script).

3. Data Management: Data Query and Export

(1) Real-Time Data Query:

The platform displays parsed real-time data reported by devices (e.g., temperature, humidity, and other measurements), supporting filtering by device/measurement point.

(2) Data Viewing and Export:

① View: Historical collected data (parsed) displayed in tables.

② Export: Supports exporting historical data (format not specified; refer to actual system functionality).

4. Device Statistics

Homepage Device Statistics:

The homepage displays device quantity and data collection statistics (e.g., device online rate, data reporting frequency), helping users quickly understand system operational status.

III. Key Function Descriptions

Custom Parsing: Personalized parsing of device data packets via JSON scripts, adaptable to different sensor types.

Collection Mode Adaptation: Supports active collection (sensors periodically upload data) and passive collection (requires sending polling commands), meeting the needs of different devices.

V. Addressing Pain Points

This solution effectively addresses the pain points of small and medium-sized enterprises (SMEs) that "want to implement energy management but face high costs and operational complexities" through an integrated strategy of "cloud deployment to reduce hardware investment, lightweight terminals for non-disruptive upgrades, and free software to minimize operational expenses." Compared to conventional approaches, it reduces upfront costs by more than 50%, shortens deployment time to 1–2 weeks (as opposed to 1–3 months with traditional solutions), and incurs nearly zero long-term maintenance costs (e.g., hardware repairs, software updates—lifetime free software upgrades are provided). Ultimately, it enables enterprises to achieve "visualized energy consumption data, digitized management processes, and precision-driven energy-saving strategies," offering a "low-cost, high-return" solution to support green transformation and sustainable development in manufacturing facilities.

VI. On-site Photos