Background

In labor-intensive enterprises, the problem to be solved urgently is to recruit suitable people who can work stably for a long time and produce high-quality products stably. Machine vision inspection technology has received extensive attention due to its outstanding advantages such as non-contact, fast speed, appropriate accuracy, strong on-site anti-interference ability, and long-term tirelessness. China is currently in the transition period from labor-intensive to technology intensive, and there is an extremely strong demand for using machine vision inspection technology to improve production efficiency and reduce labor costs.

Scheme introduction

application area

At present, machine vision recognition detection has been used in product shape, surface defect, assembly result detection and other fields, such as wood processing detection, metal surface visual detection, circuit board detection, weld defect detection, panel button installation detection, etc.

system composition

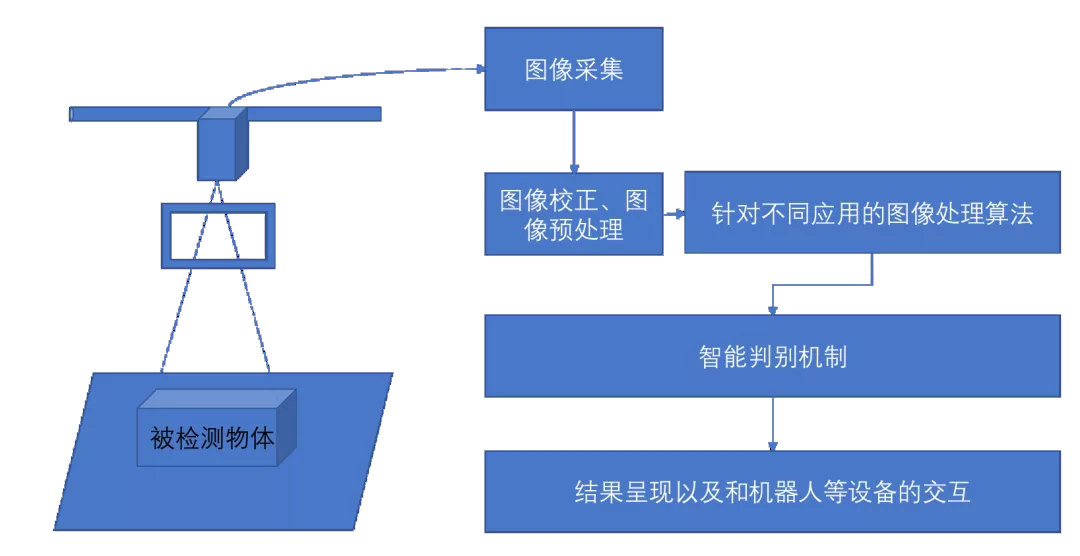

As the products in industrial production are very different, there is no uniform standard. Usually, it is the customized development of non-standard visual solutions. The visual inspection system framework provided by diffuse is as follows:

Significance value

Application case

名称:电器开关盒错装检测

行业:电器制造

方法:待检设备放置监测台,系统自动选择产品型号调取对应模板,相机固定于旋转台上方,相机采集图像,并同时进行 检测对比。检测方法基于“模版比对”,模版由标准产品创建,当无法与模版比对成功则说明产品有缺陷。

Debug picture