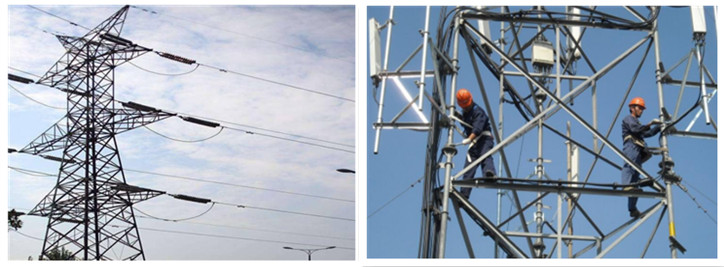

1、 Programme background

With the rapid development of electric power construction and the continuous expansion of power grid scale, more and more power grid construction and equipment maintenance work are carried out under complex terrain conditions. As the power transmission link, the transmission line has the characteristics of large dispersion, long distance, and difficult to patrol. The transmission line online monitoring system is an important part of the smart grid transmission link, and an important technical means to realize the transmission line status operation, maintenance management, and improve the lean level of production and operation management.

A smart grid construction integrator in Shanghai has jointly built a set of online safety monitoring system based on the construction process of power transmission lines with the cooperation of diffuse. Through the Internet of Things wireless transmission technology and edge algorithm, the tension and tilt of the tower during the construction process of power transmission lines are monitored online in real time, and the operation and maintenance management personnel are timely notified of any abnormalities for on-site maintenance to ensure the construction safety during the construction process.

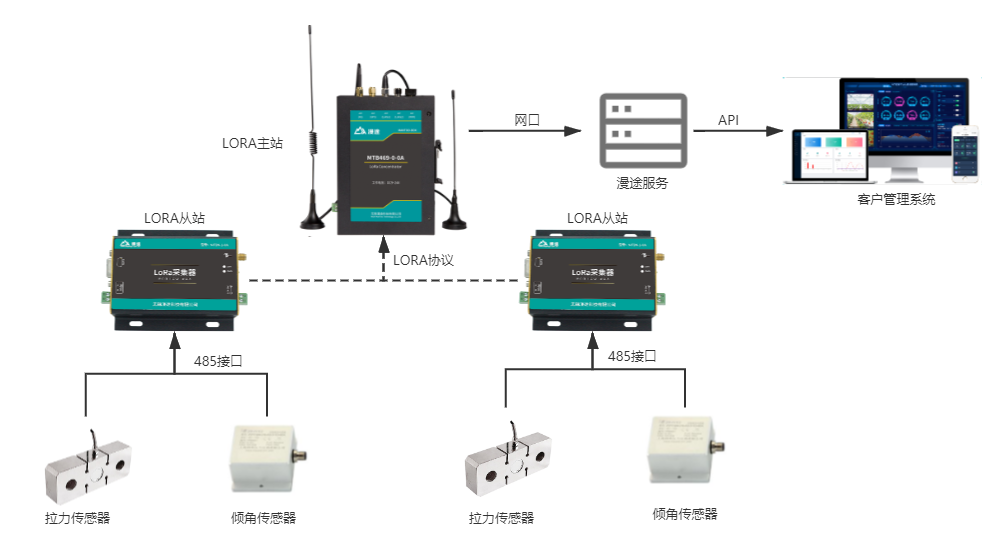

2、 System architecture

The system monitors the real-time inclination and tension value of the tower and transmission line through the inclination sensor and tension sensor, and transmits the data through the LORA LAN. Each slave station collects the collected data and sends it to the server side together with the gateway of the master station. The server edge computing (edge service) is used for diffuse travel, and then it is sent to the customer management platform through the API interface for analysis and processing. The abnormal data is sent to the alarm push, The operation and maintenance personnel shall confirm on site in time to ensure the safety control during the construction of power transmission lines and improve the safety of power transmission line construction.

3、 Hardware equipment

LORA acquisition (slave station)

The MTB9-1-0A LoRa collector uses LoRa wireless transmission technology for long-distance data transmission. High performance industrial communication processor and industrial wireless module are adopted, embedded real-time operating system is used as the software support platform, RS232 and RS485 interfaces are provided at the same time, which can be directly connected to serial devices to achieve transparent data transmission. The data storage, cycle and reporting cycle can be adjusted according to the requirements of the user environment.

LORA base station gateway (master station)

The MTB469-0-0A LoRa wireless communication base station accesses LoRa terminals of various application nodes, and the collected information is transmitted to the cloud server through 2G/4G or wired Ethernet. This product has been widely used in the M2M industry in the IoT industry chain, such as smart grid, intelligent transportation, industrial automation, intelligent buildings, fire protection, public safety and environmental protection, meteorology, digital medical care, etc.

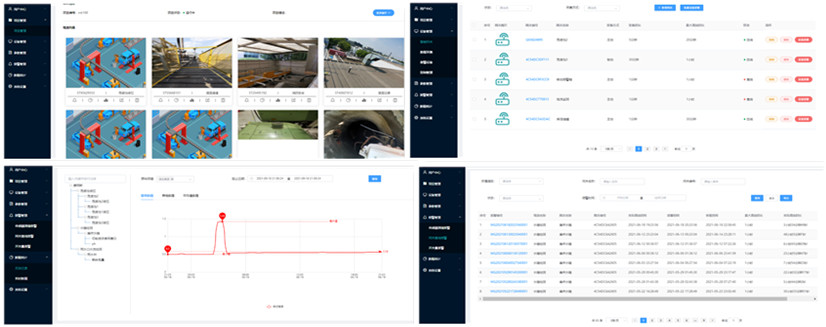

4、 System functions

Real time monitoring: support real-time data acquisition and display of inclination value and transmission line tension value;

Project management: support multiple project management, and manage multiple user sites with the same account;

Equipment management: support LORA gateway, inclination sensor and tension sensor to add and improve parameter configuration;

Data report: it supports querying the historical data collected by inclination and tension sensors, alarm information records, and batch export;

Edge service: filter the sensor transmitted by the terminal through the edge service, calculate the effective data and send it to the customer platform software;

Data forwarding: It supports the transmission of sensor tilt and pull values to the customer platform through API interfaces for data analysis and processing.

5、 Application scenario