I. Case Overview

Because tunnels can shorten mileage, protect the environment, improve alignment, and improve highway traffic conditions, modern highways often use tunnel construction when they encounter complex terrain and geological conditions. The tunnel is a concealed project underground. The underground geological conditions are complex. There are many potential and unpredictable geological factors. A little bit will cause collapse, subsidence, water inrush, deformation of supporting structure, personnel and equipment damage, etc Etc., which will seriously affect the safety of the tunnel. In order to ensure the safety and timely forecast of the danger during the construction of the tunnel, in addition to strengthening and maintaining the tunnel, monitoring and evaluation of the safety and stability of the tunnel project are also very important.

When a large state-owned enterprise construction company in Guizhou Province is constructing a tunnel, the geomorphic unit to which the tunnel traverses is the floodplain and eroded remnant landform. The terrain is generally high in the north and low in the south. To the south of Zhanqian Road is the floodplain geomorphic unit area. The area is flat. Due to various subjective and objective factors, settlement and deformation will occur. If the deformation exceeds the prescribed limit, it will affect the normal use of the tunnel. In severe cases, it will also endanger the safety of the tunnel and cause huge losses to society and people's lives. At the same time, due to the influence of tunnel construction, the original force balance state is broken, and the force is redistributed. Some original structures may produce certain deformations, including surrounding buildings, underground pipelines, existing bridges, etc. When the structure is deformed too much, it may cause the original structure to become unstable and cause some damage. The company hopes to establish an effective safety early warning monitoring system, through monitoring data, take relevant measures in advance to minimize the occurrence of disasters.

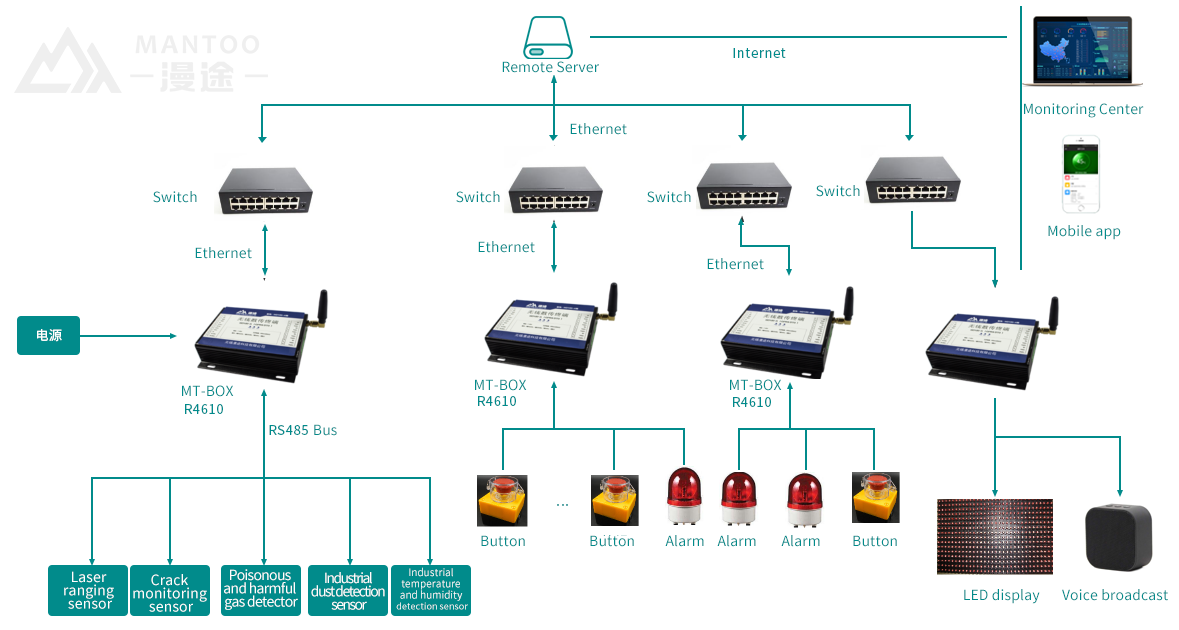

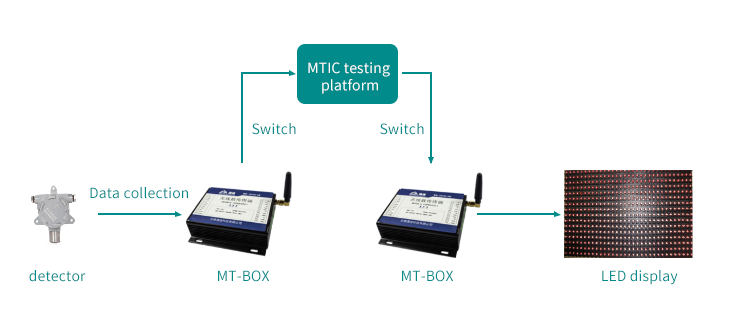

As an industrial Internet of Things service provider integrating R & D and intelligent manufacturing capabilities in the Yangtze River Delta region, MANTOO has developed a wireless transmission and automation control technology with the MT-R4610 intelligent measurement and control terminal according to the needs of the enterprise. A tunnel construction safety online monitoring cloud platform system that integrates safety monitoring, automatic remote control, and remote warning, alarm and reminder functions. The system helps the company to improve the construction process and other means to avoid the occurrence of safety accidents. At the same time, it adopts the remote warning, alarm and reminder function. When the event occurs, it promptly reminds people inside and outside the tunnel and other related personnel to take corresponding actions to reduce casualties.

II. System architecture diagram

Ⅲ. System functions

-Harmful gas monitoring: gas and combustible gas detection and toxic and harmful gas monitoring to avoid accidents caused by a lot of gas flowing out during tunnel construction and excavation

-Temperature and humidity monitoring: will strictly abide by the hygienic standard of tunnel construction operation environment.

-Dust monitoring: protect the health of construction workers on site.

-Stability monitoring: monitoring the stability of the surrounding rocks of the tunnel, grasping the working status of the support, guiding the construction forecasting the danger, making the work forecast, establishing the construction countermeasures, and monitoring the danger and safe construction

-Local display: LED screen at the tunnel entrance displays the monitoring data in the tunnel, which is convenient for the construction personnel to view directly.

-Fan linkage: when the monitoring data in the tunnel exceeds the limit (eg: dust, toxic and harmful gases exceed the standard).

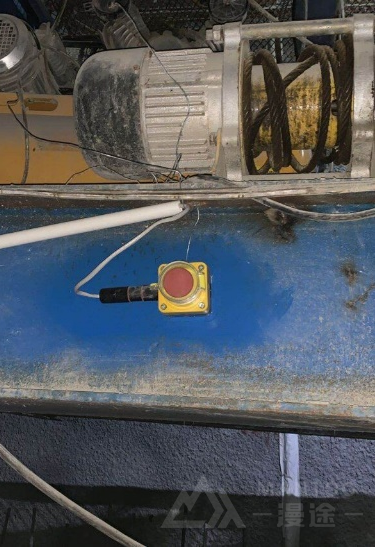

- Emergency button: The remote warning function of the emergency button notifies relevant personnel in time to reduce casualties.

-Real-time alarm: remote early warning function of monitoring data overrun, to remind the remote corresponding personnel of emergency.

-Video monitoring: You can check the construction status on site in real time.

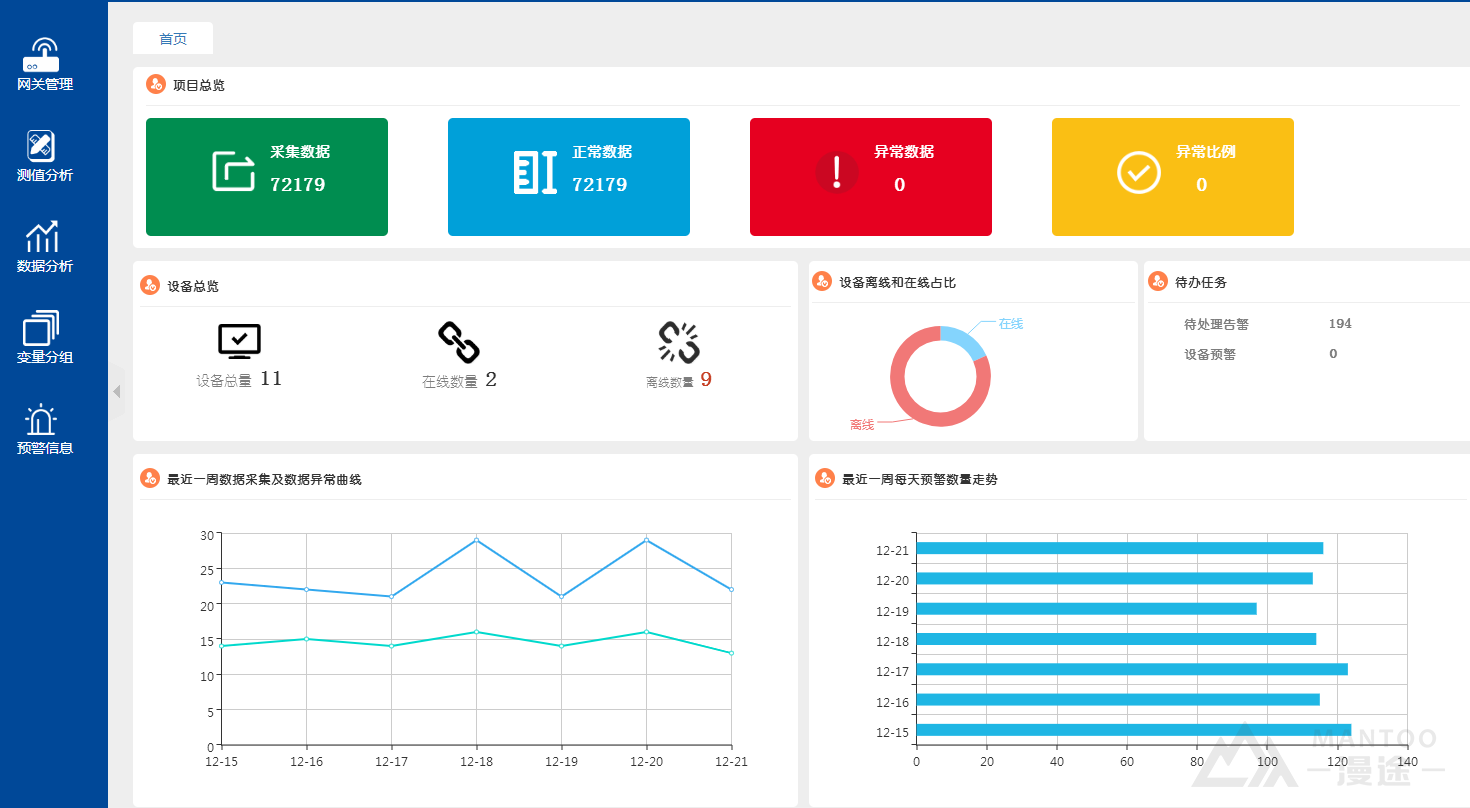

-Multi-project management: Users can monitor the construction status of multiple projects on site at the same time, which makes management more convenient.

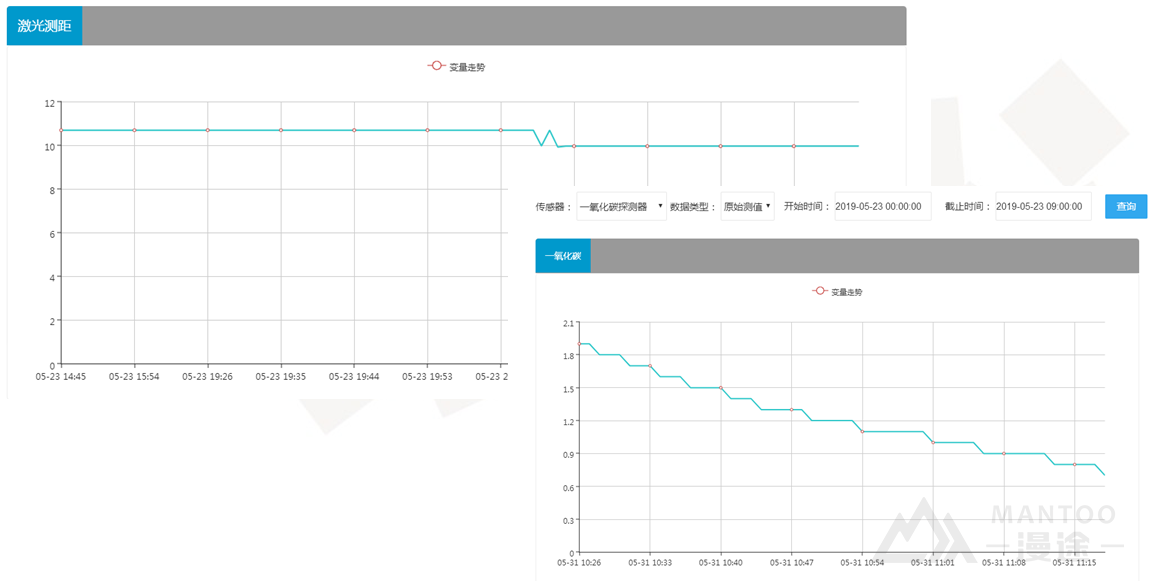

-Data cockpit: Users can view real-time data and historical data in the data monitoring center.

Ⅳ. Software system interface

Cockpit data board:

Platform monitoring data board

Management background

Real-time data curve

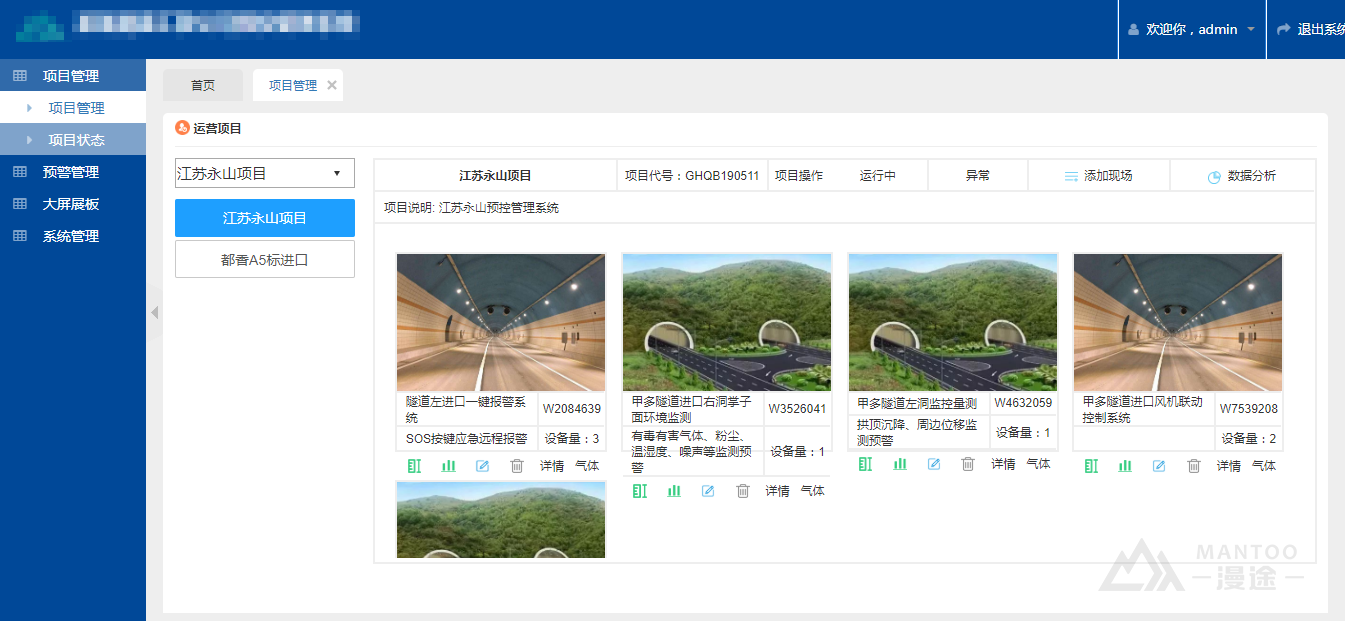

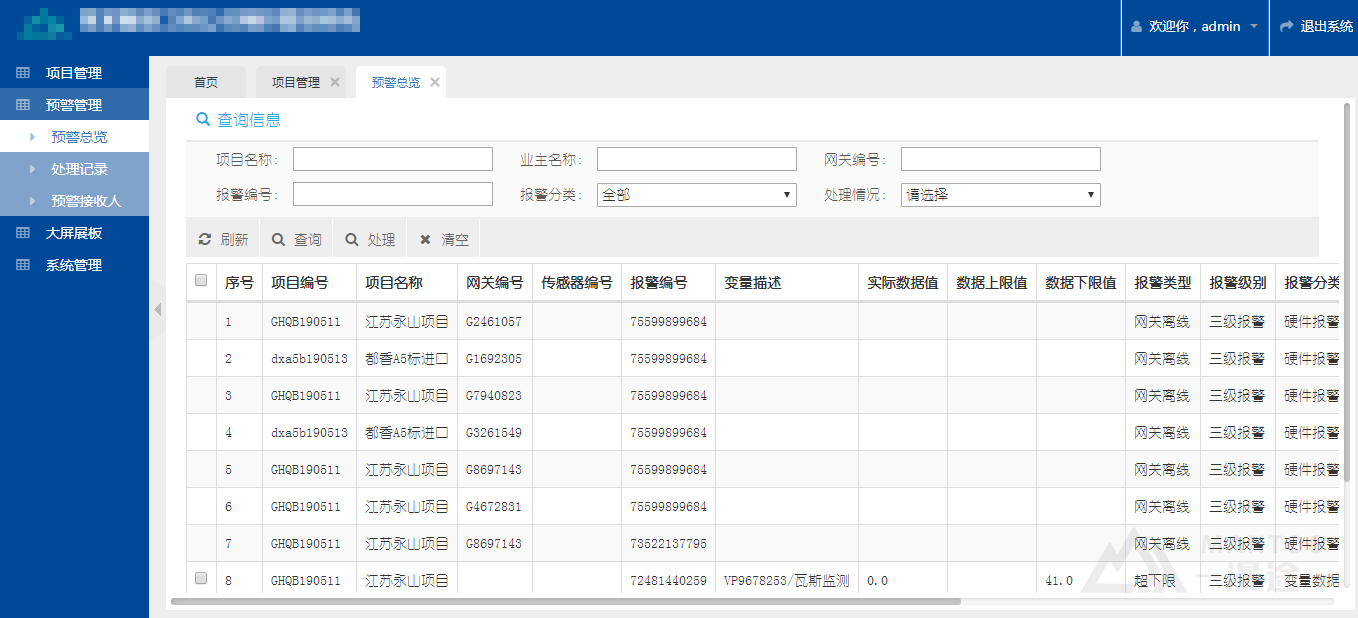

Project management interface diagram

Early warning management interface diagram

System management interface diagram

Ⅴ. Introduction to hardware products

MT-R4610 is a high-performance measurement and control device that integrates RS232 / RS485 interface, digital input, relay output, LAN port and wireless data communication. It supports RS485 device access and is an intelligent terminal device that implements wireless measurement and control. The data storage, period and reporting period can be adjusted according to the requirements of the user environment. In the system, it is mainly used for data acquisition and upload and input and output control buttons, alarm lights, LED display screens, sound and light alarms.

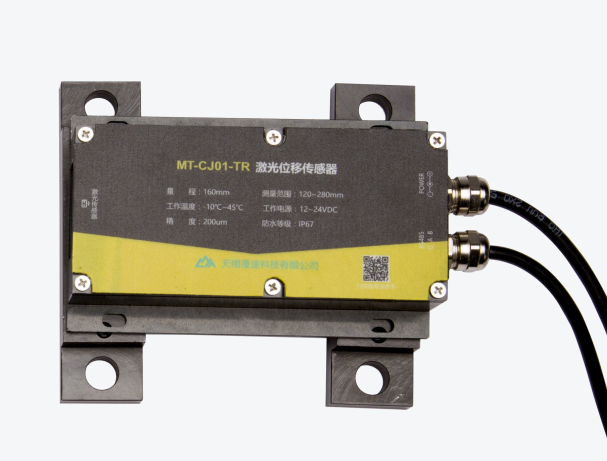

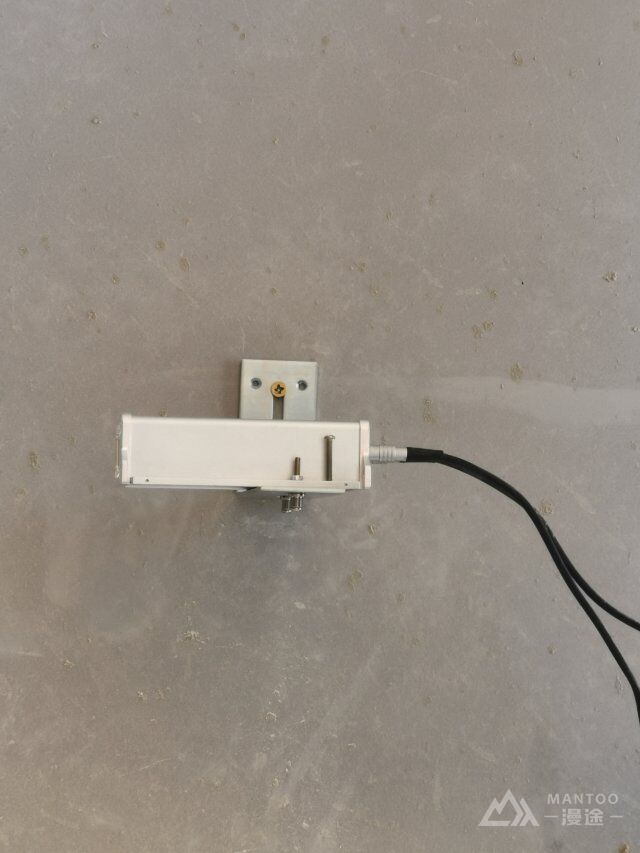

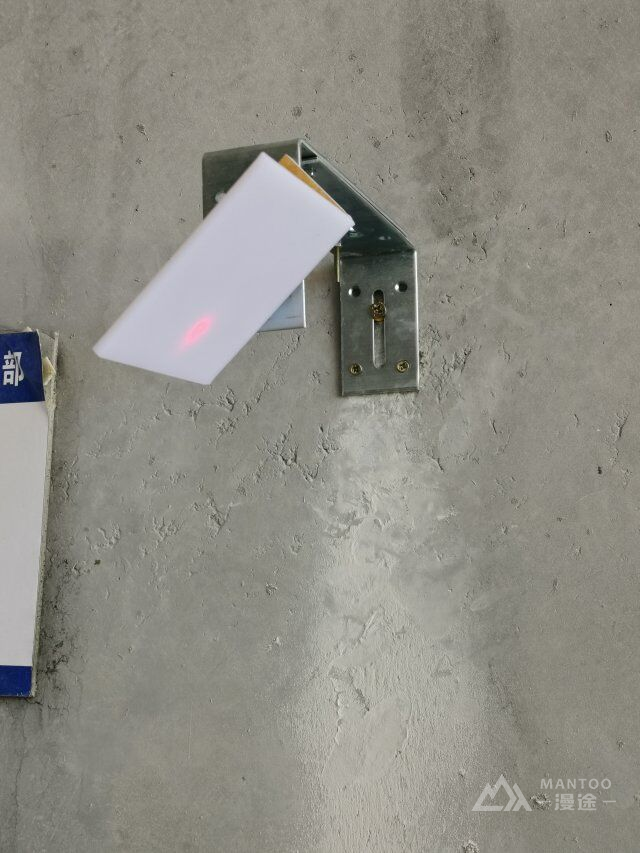

Laser displacement sensor, that is, the measurement value specified by the distance measuring sensor. High-precision CMOS image sensor used by displacement sensor. And the company's algorithm that has been used by displacement sensors has achieved a high-precision measurement of 200um.Adopt cast aluminum shell, compact size and solid body, so as to reduce the influence of unstable factors such as shell deformation and temperature on measurement accuracy.

Gas detector

Explosion-proof gas detection sensor is an instrument that can continuously detect the concentration of toxic and harmful, flammable and explosive gases in the working environment. The sensor detects the gas concentration by natural diffusion. The imported sensor has good sensitivity and excellent repeatability. The sensor uses cast aluminum material, which has high strength, temperature resistance and corrosion resistance. It is suitable for detecting the concentration of toxic and harmful gases in the ambient air. It is widely used in chemical industry, mines, tunnels, tunnels, underground pipelines and other occasions to effectively prevent accidents.

Ⅵ. On-site application photos

1) Gas flammable gas detection and toxic and harmful gas monitoring

2) Temperature and humidity monitoring

3) Dust monitoring

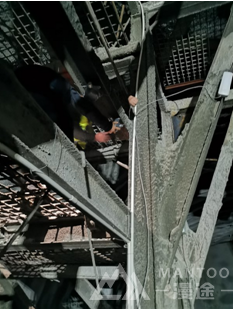

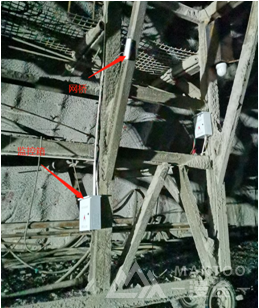

4) Stability monitoring of tunnel surrounding rock

Laser ranging sensor

5) Tunnel remote fan linkage

6) Remote display of monitoring data

In order to understand the environment of the construction site in the tunnel clearly and intuitively in real time, the construction personnel and supervisors need to display the monitoring data in the tunnel in real time. The implementation scheme is as follows:

7) Remote warning by emergency button

8) Tunnel construction video monitoring

Ⅴ. Customer evaluation

MANTOO provides us with an online monitoring system for tunnel construction safety, which greatly facilitates the management of our construction safety, ensures safe and timely forecast of danger during tunnel construction, and establishes an effective safety early warning monitoring system. In reducing accidents caused by hidden safety hazards. Among them, the remote early warning and alarm function in the system is very good. When an event occurs, one-key alarm can be made at many scenes. All scenes take emergency evacuation inside and outside the tunnel at the first time to reduce casualties.